Valves

Valves and control instruments are used for controlling the flow as well as pressure of fluids in many systems. The plug valves allow or prevent flow, whereas the control valves efficiently modulate fluid conditions for best system functionality. In terms of safety, relief valves are very important — excess pressure is automatically released to prevent damage to equipment. A butterfly valve is a versatile, process configuration with regards to large diameter pipes but has some limitations in terms of temperature and pressure due the design characteristics that limit its use for high-pressure applications such as oil and gas production; choke valves are specifically engineered control systems utilized when managing high levels of pressure drops.

Choke manifolds that include various choke valves are used in order to administer drilling fluids and well control, which helps against blowouts. Additionally, there is wellhead control equipment which offers the reassurance of oil and gas flow management coming in from wells. An actuator is a device that causes control of valve operation through the energy in different forms and allows remote or automatic controlling with added scope for improving operational performance.

Advantages

Plug Valve

Control Valve

Relief Valves

Butterfly Valve

Choke Valve

Choke Manifolds

Wellhead Control Equipments

Actuators

Size: 2″ up to 88″ (DN 50 up to DN 2200)

Pressure Rating: ASME 150# to 2500#

Materials: Carbon Steels, Low Temperature Carbon Steel, Martensitic Steels, Austenitic Stainless Steel, Duplex Stainless Steels, Super Duplex Stainless Steels, Nickel Alloys, Nickel Aluminum Bronze, Hastelloy, Inconel, Titanium Alloy & Carbon Steel with Internal Corrosion Resistant Alloy (CRA) Overlay

Design Standard: API 600, BS 1414, API 6D

Pressure / Temperature Rating: ASME B 16.34

Test (Inspection) Standard: API 598, API 6D, ISO 5208, API6FA, ISO 10497,BS6364

Construction Details: Bolted Bonnet / Pressure Seal Bonnet, OS & Y Type Rising Stem

End Connection: Flanged, Butt-Weld

Operator / Actuator: Handwheel, Gear, Actuator (Pneumatic, Hydraulic, Electro-Hydraulic and Electric Motorised)

Cryogenic Service: Gate Valves can be designed in a special version suitable for cryogenic service. In this case, all the materials and technical features are designed to withstand minimum design temperature required by the Customer, down to Cryogenic -196°C. If required by the customer, specific Cryogenic Tests are performed to verify the behaviour of production valves in terms of valve torque, sealing capability, emissions vs the ambient.

Size: 2″ up to 24″ (DN 50 up to DN 600)

Pressure Rating: ASME 150# to 2500#

Materials: Carbon Steels, Low Temperature Carbon Steel, Martensitic Steels, Austenitic Stainless Steel, Duplex Stainless Steels, Super Duplex Stainless Steels, Nickel Alloys, Nickel Aluminum Bronze, Hastelloy, Inconel, Titanium Alloy & Carbon Steel with Internal Corrosion Resistant Alloy (CRA) Overlay

Design Standard: BS 1873, API 623

Pressure / Temperature Rating: ASME B 16.34

Test (Inspection) Standard: API 598, ISO 5208, BS 6364

Construction Details: Bolted Bonnet / Pressure Seal Bonnet, OS & Y Type Rising Stem

End Connection: Flanged, Butt-Weld

Operator / Actuator: Handwheel Gear, Actuator (Pneumatic, Hydraulic, Electro-Hydraulic and Electric Motorised)

Cryogenic Service: Globe Valves can be designed in a special version suitable for cryogenic service. In this case, all the materials and technical features are designed to withstand minimum design temperature required by the Customer, down to Cryogenic -196°C. If required by the customer, specific Cryogenic Tests are performed to verify the behaviour of production valves in terms of valve torque, sealing capability, emissions vs the ambient.

Size: 2″ up to 56″ (DN 50 up to DN 1400)

Pressure Rating: ASME 150# to 2500#

Materials: Carbon Steels, Low Temperature Carbon Steel, Martensitic Steels, Austenitic Stainless Steel, Duplex Stainless Steels, Super Duplex Stainless Steels, Nickel Alloys, Nickel Aluminum Bronze, Hastelloy, Inconnel, Titanium Alloy & Carbon Steel with Internal Corrosion Resistant Alloy (CRA) Overlay

Design Standard: API 6D, API 594, BS 1868

Pressure / Temperature Rating: ASME B 16.34

Test (Inspection) Standard: API 598, API 6D

Construction Details: Bolted Cover / Pressure Seal Bonnet, Swing Check, Tilting Disc, Non – Slam Check

End Connection: Flanged, Butt-Weld

Operator / Actuator: Handwheel Gear, Actuator (Pneumatic, Hydraulic, Electro-Hydraulic and Electric Motorised)

Size: 2” up to 56“ (DN 50 up to DN 1400)

Pressure Rating: ASME 150# to 2500#

Materials: Carbon Steels, Low Temperature Carbon Steel, Martensitic Steels, Austenitic Stainless Steel, Duplex Stainless Steels, Super Duplex Stainless Steels,Alloys, Nickel Aluminum Bronze, Hastelloy, Inconel, Titanium Alloy & Carbon Steel with Internal Corrosion Resistant Alloy (CRA) Overlay

Design Standard: API 6D, API 608

Pressure / Temperature Rating: ASME B 16.34

Test (Inspection) Standard: API 6D, ISO 5208 API 6FA, ISO 10497, API607, BS 6364

Construction Details: Single / Two / Three Piece Design / Side Entry

End Connection: Flanged, Butt-Weld

Operator / Actuator: Lever, Gear, Actuator (Pneumatic, Hydraulic, Electro-Hydraulic and Electric Motorised)

Special Design Feature also available: Cryogenic Design, Subsea Design,Stem Extension,Single & Double, Piston Seat Design, Primary Metal and Secondary Soft Seat Design, Emergency Seat and Stem sealant Injection Through the Development, Design, Manufacture, and supply of high-quality industrial valves with the goal of zero rate dismissal, we are focused on achieving total customer satisfaction. As the Top ball valve suppliers we take in use quality service and constant development. So for the buyer, looking for great ball valve manufacturers you have come to the Right Place.

Size: 5” up to 8“ (DN 15 up to DN 200)

Pressure Rating: ASME 150# to 2500#

Materials: Carbon Steels, Low Temperature Carbon Steel, Martensitic Steels, Austenitic Stainless Steel, Duplex Stainless Steels, Super Duplex Stainless Steels,Alloys, Nickel Aluminum Bronze, Hastelloy, Inconel, Titanium Alloy & Carbon Steel with Internal Corrosion Resistant Alloy (CRA) Overlay

Design Standard: API 6D, ISO 17292

Pressure / Temperature Rating: ASME B 16.34

Test (Inspection) Standard: API 6D, API 6FA, API607

Construction Details: Single / Two / Three Piece Design / Side Entry

End Connection: Flanged, Socket-Weld

Operator / Actuator: Lever, Gear, Actuator (Pneumatic, Hydraulic, Electro-Hydraulic and Electric Motorised)

Special Design Feature also available: Cryogenic Design, Stem Extension, Primary Metal and Secondary Soft Seat Design

Standards: ASTM, ASME, API, BS, DIN, NACE MR‐ 01‐75

Grades: Chrome, Moly, Aluminum, Duplex, Alloy steel, Inconel, Nickel Alloys, Hastelloys, Titanium A193, A194, A320 B7, B7M, 2H, 2HM, L7, L7M, 7, 4, B8, B8M, 8, 8M, B16

Types: Stud Bolts, Anchor Bolts, Turbine Bolting, High Tensile Threaded Rods, Hex Head Bolt, Cap ,Screws, Nuts, & Washers.

Threading: ISO System‐Triangular proof thread, Symmetric Trapezoidal, thread, ISO Pipe Thread. ASA System‐UNC Triangular Profile thread (Standard Services), UNF Triangular Profile Thread (Special Series), NPT Conical Thread with Triangular Profile ACME Trapezoidal profile thread.

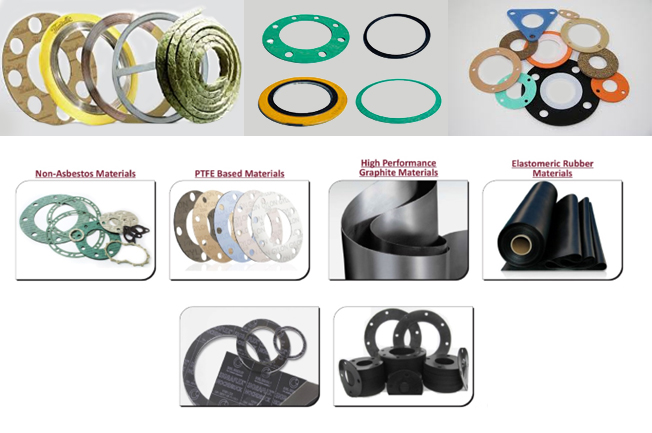

A versatile range of gaskets including compressed fiber, Klinger spiral hound, graphite self-centering or centering ring type.

Orifice Plate

Orifice Assembly

Padlock

Spare Parts

Fittings – Piping: Tubing and Hoses

Coupler

Flexible connector

Flexible metal hoses

Quick connect hose couplings

Restriction Office

Venturi tube

Pitot Tube

Condensate Chambers

Flow Conditione

Download Brochure

Download Brochure